Structural Engineering

The intersection of art and engineering.

Structural packaging provides more than simply protecting the product during transit. A successfully designed package incorporates the brand identity through its materials, shape and form, translating into added value to the product, aiding in the increase of store sales and top line growth.

Our experience in developing innovative packaging solutions for all types of products, combined with our global manufacturing capabilities and graphic services, provide our clients with decreased production cycles that save time, cost and worry.

- Competitive Costs

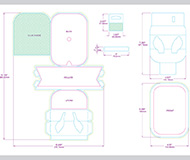

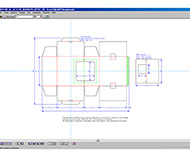

- 3D Illustrations and Concepts

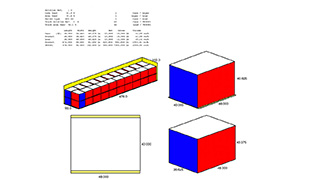

- Master Carton Planning

- Mock-up and Fit Samples Provided

- Innovative Solutions to Reduce Packaging

- Designed for Structural Integrity

- Customer Regulation Assessment

- Evaluation for Cost Savings

- Consultation on Packaging Alternatives

- Product Transit Analysis

Value and Results Delivered

r-pac’s structural packaging solutions are designed to meet the requirements of international testing standards and the rigorous demands of global supply chains.

All packaging structures engineered by r-pac begin with the end in mind. We analyze the merchandise and current packaging, provide our clients with fit samples and 3D illustrations, and packaging assembly support to ensure no delays.

Our skilled engineers collaborate with our graphic designers and manufacturers to create packaging that meets the high expectations and competitive demands of our customers and delivers bottom line savings in assembly and packout.

Packaging Design Technologies

A full suite of resources are available to develop your next package. Industry standard structural software including ArtiosCAD and Solidworks are used to develop innovative and precise structures tailored to specific products. Our global resources allow for design in one region, while adjusting and sampling in another.

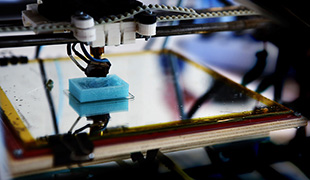

Equipped with Stratasys 3D Printers and ESKO Kongsberg Cutting Tables, r-pac has the tools and capacity to design and produce paper and plastic prototypes and mock-ups in house.

We are strategically located around the world to provide samples when and where they are needed. r-pac’s structural packaging solutions are designed to meet the requirements of international testing standards and the rigorous demands of global supply chains.

Master Carton Planning and Containerization

r-pac employs CAPE software to plan and develop master carton packing options to optimize packout for product manufacturers.

r-pac calculates and maximizes container shipments with the aim to minimize damages and deliver optimal results in global supply chains.

Quality Assured Through Testing

r-pac is fluent in ISTA international transit test requirements and test methods and has the resources to ensure there are no surprises during shipment. These standard tests include: drop tests, Edge Crush Tests, Burst Tests, and Moisture/Temperature Tests.

r-pac is also equipped with XRF screening technologies to address toxics in packaging compliance.

Contact us today to learn more.